Hobbyists and DIY enthusiasts also benefit from the capabilities of heavy-duty machines. For those who enjoy crafting their own clothes or home décor, the ability to handle thicker fabrics opens up a world of creative possibilities. Utilizing these machines can lead to professional-looking results that elevate personal projects.

Before you start sewing, you need to select the appropriate twin needle for your project. Twin needles are available in different widths (the distance between the two needles) and thicknesses. A wider spacing is ideal for techniques like pintucks, while a narrow spacing is better for sewing on knits and lightweight fabrics. Additionally, consider the size of the needle itself; a thicker needle is better for heavier fabrics like denim, while a finer needle works well with more delicate materials.

The Importance of Professional Upholstery Sewing Machines

1. Increased Efficiency Using appropriate strong needles can enhance sewing efficiency. Needles designed for heavy fabrics can move through the material with ease, reducing the risk of breakages or skipped stitches. This efficiency is particularly important for professional seamstresses or those who undertake large sewing projects.

3. Wide Throat Space When working with large pieces of leather, having enough throat space to maneuver the fabric is vital. A wider opening allows you to handle bulky items better, making it easier to sew bags, belts, or upholstery.

A traditional hand-powered leather sewing machine is designed specifically for sewing leather, which is known for its durability and thickness. These machines typically feature robust metal construction, ensuring longevity and stability during use. The most notable component is the hand crank, which allows the user to control the sewing speed and stitch precision. This manual control is highly valued as it enables craftsmen to manage delicate curves and intricate designs that automated machines might struggle with.

- Reduced Fabric Bulk The overlock chain stitch lays flatter than other sewing techniques, which can help reduce bulkiness, especially at seams. This is particularly important in areas where comfort and fit are paramount, such as cuffs and necklines.

Price

Warranty

Price Ranges

Reduced Error and Waste

4. User-Friendly Operation With many modern models designed with intuitive interfaces and robust software, operating a two needle embroidery machine has become accessible even for beginners. Comprehensive tutorials and guides often accompany these machines, providing users with the resources needed to get started.

Mechanics of the Walking Needle

The role of bag seaming machines extends beyond mere convenience. They enhance productivity, reduce labor costs, and minimize waste while ensuring product integrity. In industries such as agriculture, food packaging, and pharmaceuticals, maintaining the quality of the contents is non-negotiable, and effective bag sealing is crucial to achieving this goal.

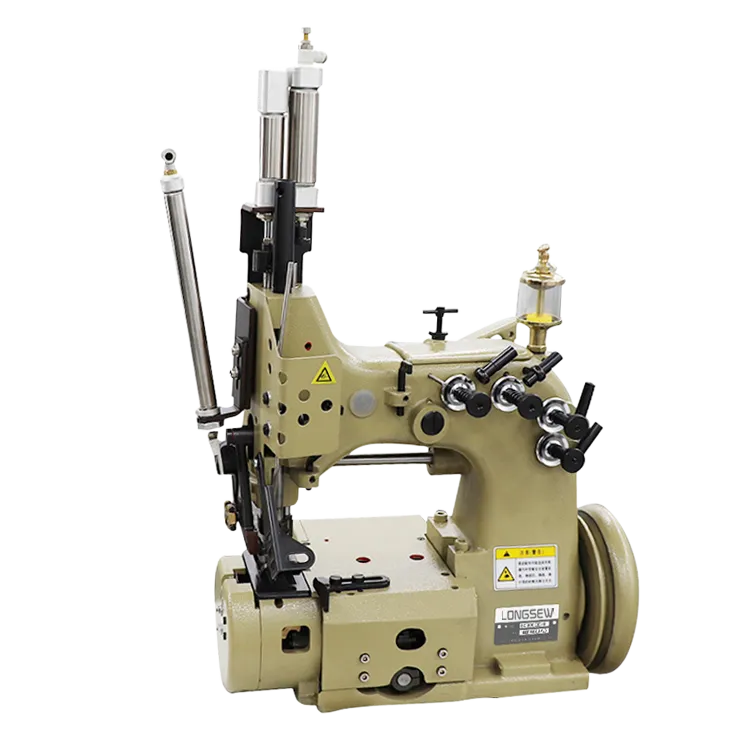

bag seaming machine

3. Build Quality The materials and craftsmanship that go into a sewing machine significantly impact its durability and performance. Machines constructed with high-quality materials, such as metal frames and components, are generally more expensive but offer greater longevity and stability during use. For those planning to use their machine frequently, investing in a higher-quality model may pay off in the long run.

One of the main advantages of a double needle walking foot sewing machine is its ability to handle a wide variety of fabrics effortlessly. Whether you are working with heavy materials such as denim and canvas or delicate fabrics like lace and chiffon, this machine provides the stability and control needed to achieve professional results. It is particularly favored by quilters and garment makers who require precision and durability in their sewing projects.

Finishing Up

What is an Industrial Sewing Machine?

Creative Freedom and Artistic Expression

4. High-speed Embroidery The speed at which these machines operate is another major benefit. With the capability to produce high-quality embroidery at rapid speeds, they enable businesses to meet tight deadlines and increase overall production capacity.

two needle embroidery machine

4. Level of Automation Fully automated machines that require minimal human intervention tend to be pricier than manual or semi-automatic machines. The benefits of automation often justify the investment, as they can reduce labor costs and increase overall efficiency.

Using a sailmaker sewing machine not only enhances the quality of the finished product but also significantly reduces the time and effort required to fabricate sails. In a world where efficiency is paramount, having the right tools can mean the difference between meeting deadlines and falling behind. Additionally, the precision that these machines offer ensures that sails are not just aesthetically pleasing but also functionally effective, providing the necessary aerodynamic properties needed for efficient sailing.

2. Durability and Speed Commercial models are built for heavy-duty use, making them ideal for busy sewing environments. They are equipped with powerful motors that can sew at high speeds, thereby increasing productivity. This feature is particularly beneficial for businesses that require quick turnaround times.

commercial zig zag sewing machine

Additionally, the machine’s design minimizes the likelihood of common sewing issues, such as thread breaking or tension irregularities. Many users report that the Cub Leather Sewing Machine provides consistent performance, allowing them to complete projects efficiently and to a high standard.

Sewing machine specials are often rolled out during various sales events throughout the year—think Black Friday, Cyber Monday, or even seasonal sales. These promotions can include discounts on specific brands or models, bundled accessories, or even financing options that make purchasing a new machine more accessible. For many, these specials can be a golden opportunity to invest in a higher-end machine that might have otherwise been out of reach.